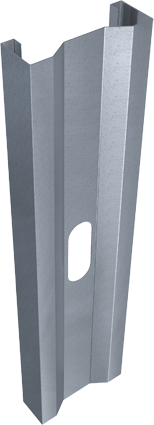

Panelization Products

PeerEngine offers a wide range of structural engineering design services for cold-formed steel framing. Architects, engineers, general contractors, and framing contractors obtain greater insight into their projects with PeerEngine on their team. PeerEngine offers Comprehensive Shop Drawings and Advanced BIM Shop Drawing & Estimation Packages. PeerEngine is comprised of the industry’s most knowledgeable, trusted team of CFS design experts to support Shop Drawing and BIM projects.

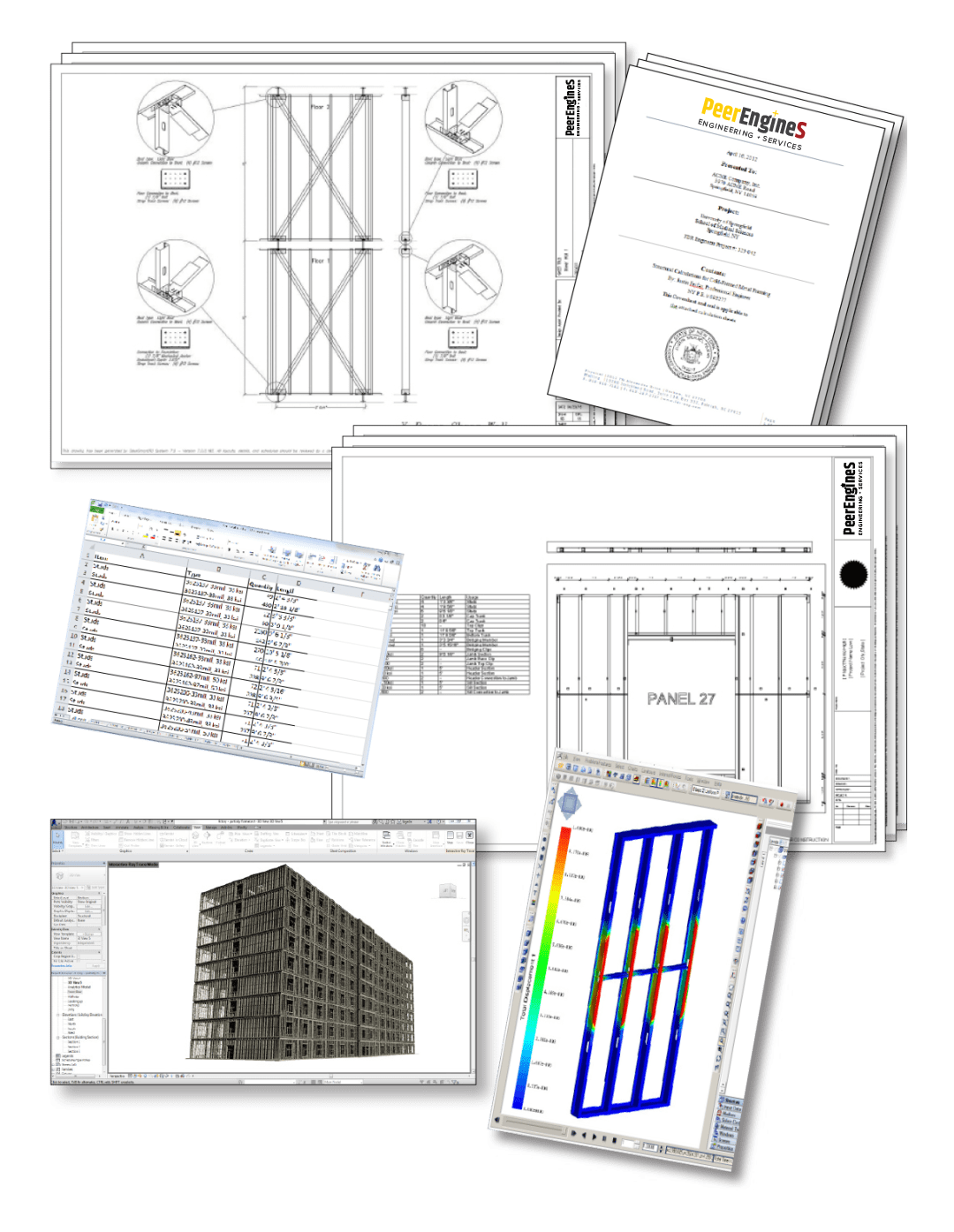

Comprehensive Shop Drawings:

- Engineered Shop Drawings

- Structural Calculation Package

- Sealed by a Licensed Professional Engineer

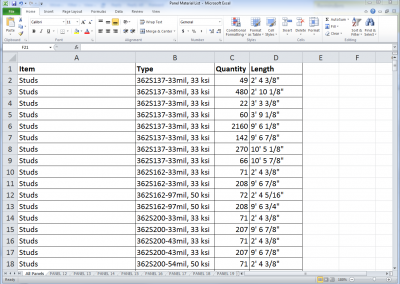

Advanced Design & Estimating:

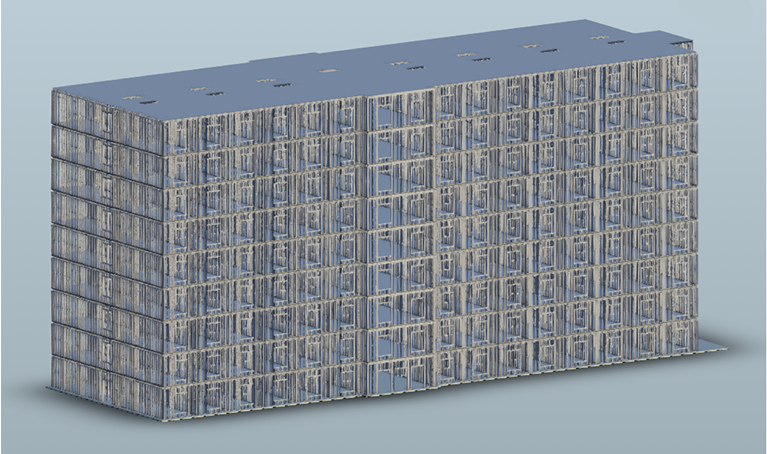

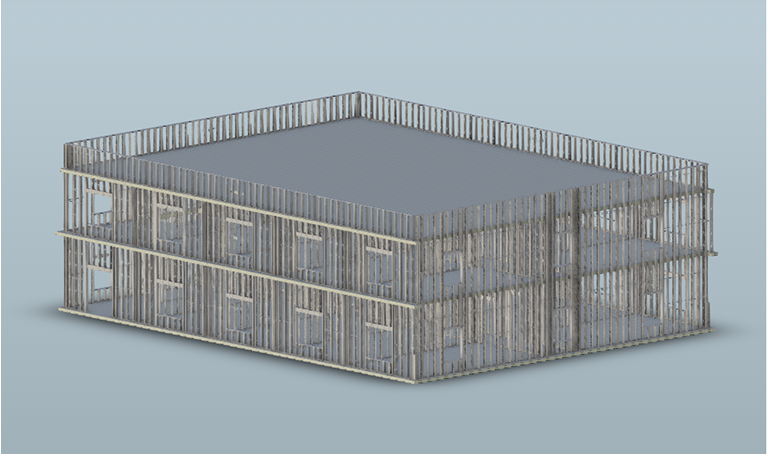

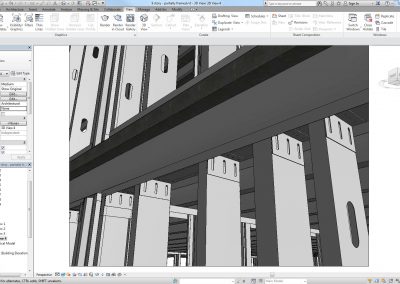

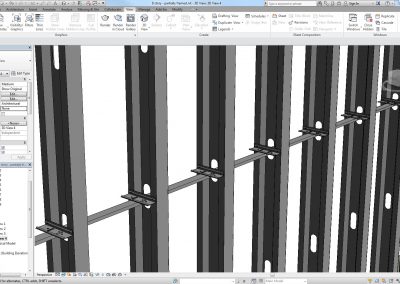

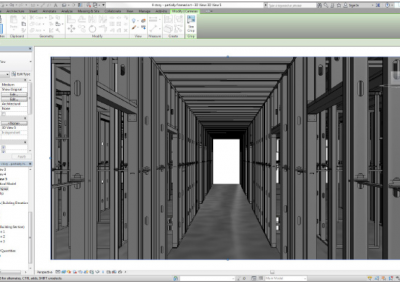

- 3D BIM Model

- Material Take-Off in excel format for all framing & connectors

- Plan Layouts

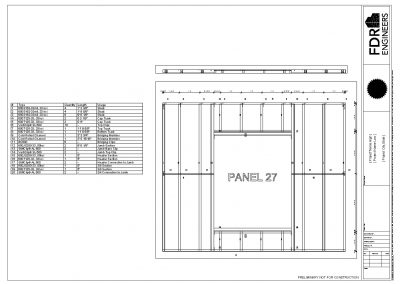

- Panel Drawings

Advanced Analysis:

- Performance Based Design

- Progressive Collapse Analysis

- Blast Analysis of Wall and Roof Truss Systems to DoD Requirements

3-D Cloud Based Project Collaboration

Proven Materials

The ISEAL EP system uses proven silicone materials. Silicone has been used for over 40 years in conjunction with STO products.

Faster Dry-In

With the ISEAL-EP system the 4-Way splice joints are installed as the panels are erected, providing completed panel perimeter joints with each installed panel. With traditional sealant/backer rod joints the joints are typically installed after all panels are installed, leaving the building exposed to the elements during construction.

Proven Performance

The ISEAL EP system, including the exoskeletal 4-way splice has been subjected to rigorous laboratory testing to validate system performance.

Factory Installation Quality

Over 90% of the ISEAL EP system is shop installed in a controlled environment with rigorous quality control, eliminating the quality challenges of field installed sealant/backer rod joints.

Faster Dry-In

With the ISEAL-EP system the 4-Way splice joints are installed as the panels are erected, providing completed panel perimeter joints with each installed panel. With traditional sealant/backer rod joints the joints are typically installed after all panels are installed, leaving the building exposed to the elements during construction.

Movement Capacity

The ISEAL EP gasket is highly flexible and able to easily accommodate building movements while imparting lower loads on the panel joints as compared to a traditional sealant/backer rod joint. This reduces the risk of adhesive joint failure.

Example Steel Framing BIM Models

Example Hotel BIM Model

Example Office BIM Model

Benefits of Steel Framing:

- Lower Costs – Steel framing has the highest strength-to-weight ratio of any building system, results in no hidden construction costs related to fire safety for combustible framing systems, and results in lower insurance rates.

- Increased ROI – Quicker & easier installation with completely straight studs and joists mean less time on the job-site. Also there are no height or floor size restrictions allowing for maximal use of land footprint.

- Resists High Seismic & Wind Conditions – Steel is an inherently stable, manufactured material that is both consistent and ductile making it more efficient than wood in withstanding such major events as fire, earthquake & high wind

- Corrosion Resistance – The protective zinc coating over cold-formed steel will last nearly 700 years before the level of corrosion resistance deteriorates

- Mold Resistance – Steel does not retain water and unlike wood framing, cold-formed steel is inorganic and won’t provide a source for mold and mildew.

- Resists Termites & Pests –Termites represent a significant threat to the long-term resilience of a building throughout most of the U.S. CFS is one of the few materials that can resist termites in nearly any climate or building type

- Does Not Burn – The performance of steel components and steel structures in fire has been researched more extensively than any other building material. Cold-formed steel does not burn and will not contribute to the spread or intensity of a fire.